About Baniar Polymer Company

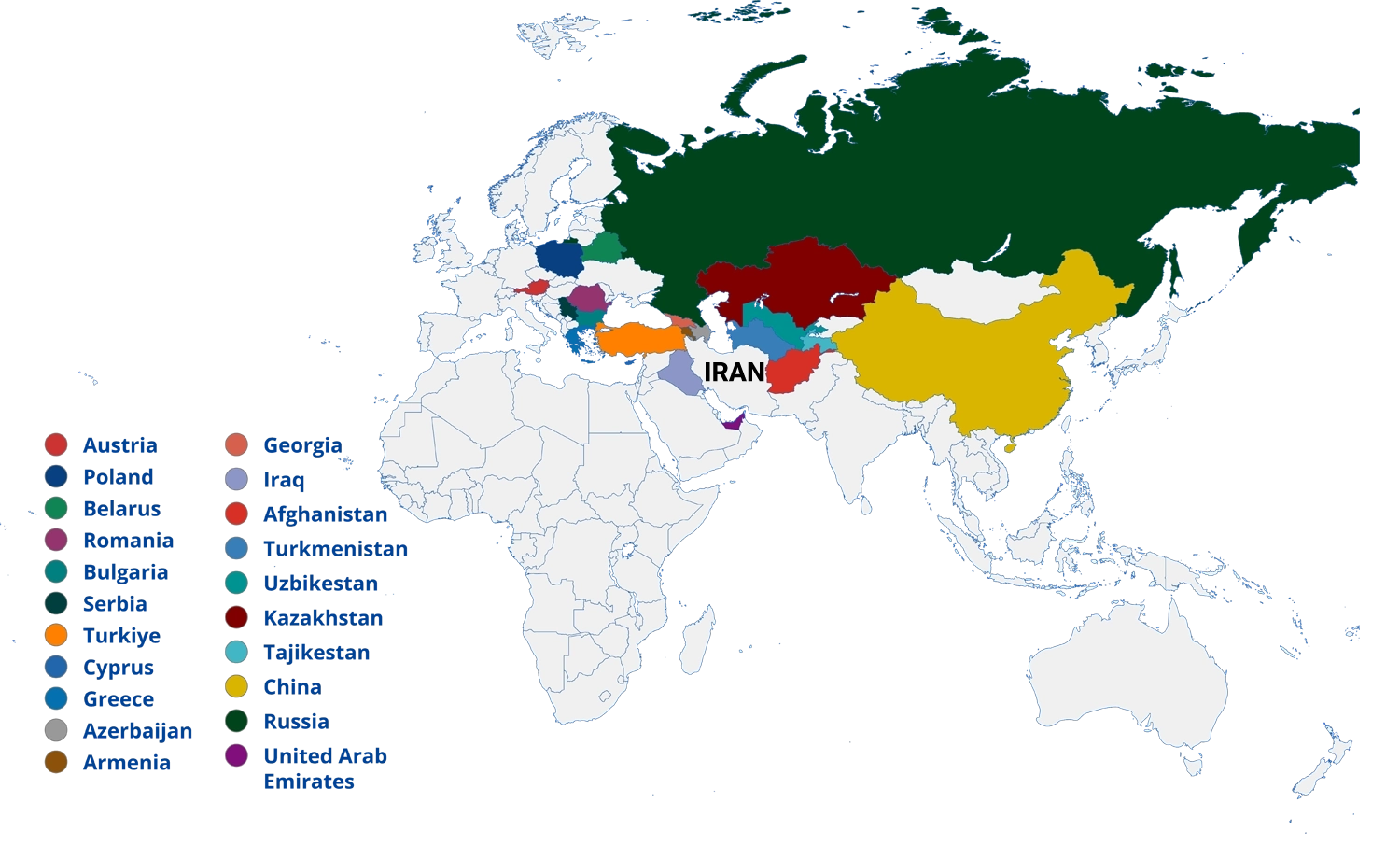

Baniar Polymer is the first and the largest manufacturer of Flame Retardant Expandable Polystyrene (EPS) in Iran. With over 205,000 tonnes of annual capacity, it covers domestic, Europen, CIS and Middle markets.

Following commissioning of its lastet production line expansion in December 2023, this capacity will reach to 315,000 tonnes annually.

Baniar Polymer is an offspring of Baniar Inc. which is a private entity established in 1978 with its first activity on providing construction solutions. Baniar Polymer was established in 2013 in the industrial area of Gonbad-e Kavus, north-east of Iran.

Baniar Inc. is a private entity and was established in 1978 with its first activity on providing construction solutions.Baniar Polymer was established in 2013 in the industrial area of Gonbad-e Kavus, north-east of iran.

At Baniar Polymer, we are fully committed to manufacturing our products with the highest quality to meet our customers’ demands for a sustainable future. We believe in combining economic prosperity with social responsibility and environmental protection.

Baniar Polymer’s practical philosophy is based on doing its best in addressing industry demands with technological solutions to help our customers be more efficient, enhance their existing products and develop new opportunities.

About

Baniar Polymer

Company

Baniar Polymer is the first and the largest manufacturer of Flame Retardant Expandable Polystyrene (EPS) in Iran. With over 205,000 tonnes of annual capacity, it covers domestic, Europen, CIS and Middle markets. Following commissioning of its lastet production line expansion in December 2023, this capacity will reach to 315,000 tonnes annually. Baniar Polymer is an offspring of Baniar Inc. which is a private entity established in 1978 with its first activity on providing construction solutions. Baniar Polymer was established in 2013 in the industrial area of Gonbad-e Kavus, north-east of Iran.Baniar Inc. is a private entity and was established in 1978 with its first activity on providing construction solutions.Baniar Polymer was established in 2013 in the industrial area of Gonbad-e Kavus, north-east of iran. At Baniar Polymer, we are fully committed to manufacturing our products with the highest quality to meet our customers’ demands for a sustainable future. We believe in combining economic prosperity with social responsibility and environmental protection. Baniar Polymer’s practical philosophy is based on doing its best in addressing industry demands with technological solutions to help our customers be more efficient, enhance their existing products and develop new opportunities.

Baniar Polymer

Baniar EPS Specific Characteristics

Our Laboratory controls the quality and properties of raw materials and end products. To ensure the purity of our raw materials such as Pentane and Styrene Monomer, Gas Chromatography Analysis us carried out on batch-to-batch basis. In addition to that we perform the required tests to monitor the quality of the end products and their particle size, shape and stability.

Baniar Polymer

Baniar EPS Specific Characteristics

Our Laboratory controls the quality and properties of raw materials and end products. To ensure the purity of our raw materials such as Pentane and Styrene Monomer, Gas Chromatography Analysis us carried out on batch-to-batch basis. In addition to that we perform the required tests to monitor the quality of the end products and their particle size, shape and stability.

In What Packaging Is Baniar EPS Offered?

Large bulk bags, each weighing 1000 kilograms.

In What Packaging Is Baniar EPS Offered?

Double-layer laminated Kraft bags, each weighing 25 kilograms.

Large bulk bags, each weighing 1000 kilograms.

Baniar PolymerEnvironmentally Friendly

Baniar Polymer

Environmentally Friendly

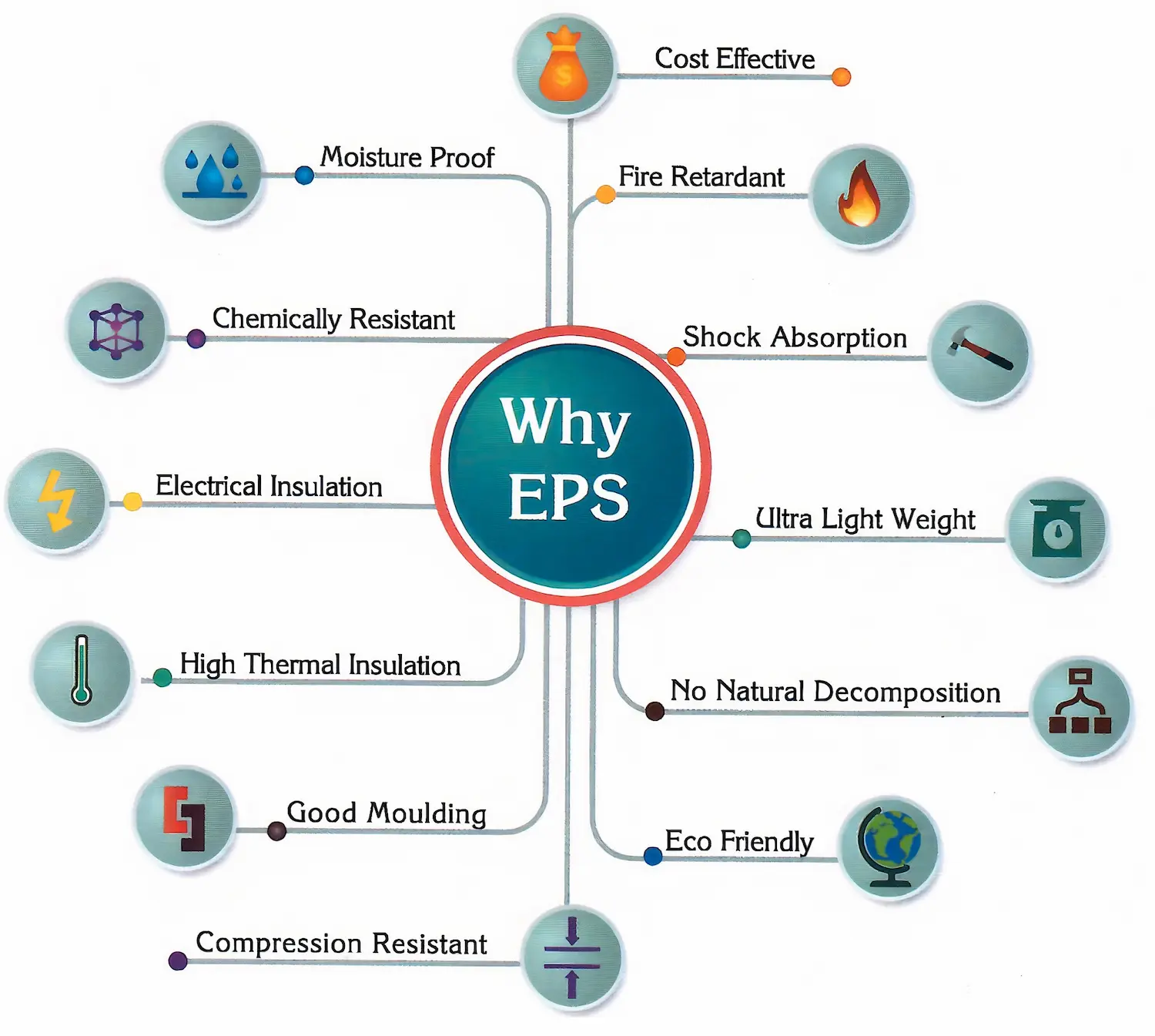

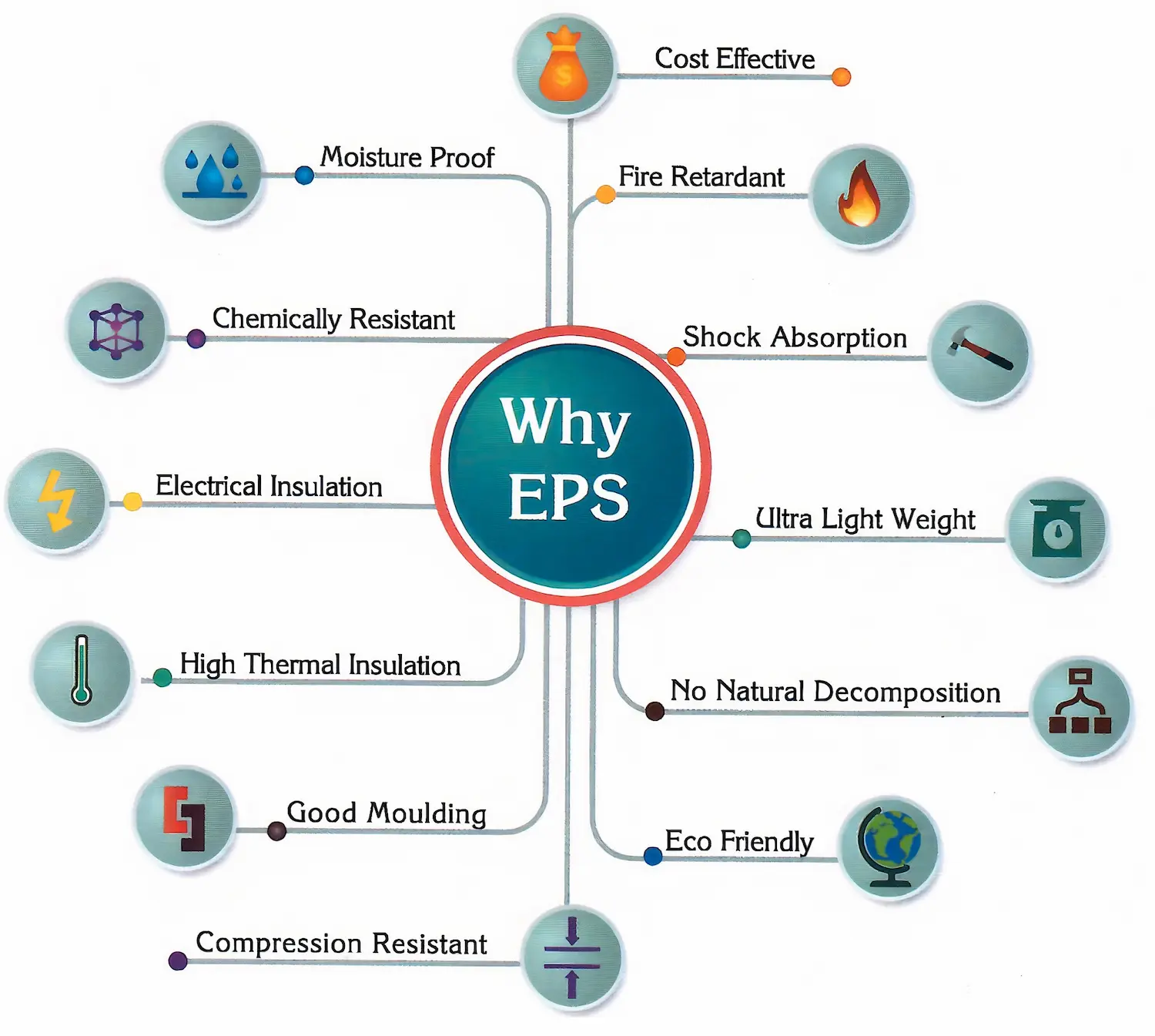

Why should we use flame-retardant Expanded Polystyrene (EPS)?

Baniar Polymer meets customer needs with high-quality assurance, expandable properties, and the desired density.

Expandable Polystyrene (EPS)

- Ultra Light Weight

- Moisture Proof

- Fire Retardant

- Good Moulding

- Compression Resistant

- No Natural Decomposition

- Eco Friendly

Applications of EPS

- Building Thermal Insulation

- Food Packaging and Cutlery

- Road and Sub-pavement Flooring

- Toys And House Stuff

- Horticulture and Garden

- Decoration of Building

Our Partners

Baniar Polymer Exports

Baniar World Global

Baniar Polymer Exports

Baniar World Global

Latest News and Educational Content

This section provides explanations and educational materials about Baniar Polymer's activities.

Latest News and Educational Content

This section provides explanations and educational materials about Baniar Polymer's activities.

Environmentally Friendly

Having this feature means being earth-friendly or non-damaging to the environment. This term typically refers to products that support a green lifestyle or methods that help conserve resources such as water and energy. Baniar products, with their structural features, effectively contribute to this goal.

Ozone Friendly

Having the feature of being free from CFCs and HCFCs means that the product does not contain substances that are harmful to the ozone layer. Chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) are organic compounds that consist solely of hydrogen, carbon, chlorine, and fluorine, and are produced as volatile derivatives of methane, ethane, and propane.

EPS Recycling

Recycling EPS helps turn packaging waste into valuable resources. This process involves reducing consumption, reusing, recycling into new materials, and energy recovery. EPS recycling programs include compression, collection, shredding, mixing, and extrusion to produce new products with added value.

Certifications

Baniar Polymer, a leading company in the petrochemical industry, specializes in producing high-quality polystyrene products. The company holds reputable international and domestic certifications in Iran. Baniar Polymer's commitment to quality and environmental protection makes it a top choice in the industry.